Asphalt Performance Testing

BATT can perform the type of complex testing required to help contractors meet constantly evolving specifications.

BATT Asphalt Performance Testing —

Data-driven solutions for safer, more sustainable roadways

Friction Testing

Expect friction testing to continue to gain prominence in future roadway specification. Tests are ongoing at the National Center for Asphalt Technology (NCAT) test track, and NCAT has led the way in the U.S. on friction testing and correlations with traffic and skid trailer data. Given the level of attention friction testing is receiving, it’s a good idea to begin establishing a relationship with a reliable testing resource.

On average, the BATT Lab can complete a friction test in 4 to 5 days. The entire testing process can determine the long-term friction properties of any aggregate or asphalt mix ahead of paving — and for a substantially lower cost, shorter time frame, and no risk to the traveling public — than waiting years to measure the pavement wear.

Will your mix pass DFT?

Future bids will need to consider how to increase the amount of polish-resistant aggregates, as many state agencies add requirements to ensure all pavement designs be submitted to a Dynamic Friction Test (DFT). DFT is a newer, more intuitive testing tool. It measures skid resistance with a rubber-padded plate that spins at highway-level speeds before dropping onto the surface of the asphalt test sample. This important advancement in testing enables agencies and contractors to quickly evaluate aggregate sources ahead of paving rather than waiting five to 10 years for highway results. Best of all, the DFT can travel from the lab to the field for real-time data and correlation.

Scuff Testing

Scuff testing is a specialized performance evaluation that measures how well an asphalt mix resists surface wear under high-shear, low-speed stress conditions—like those found at intersections, roundabouts, parking lots, and loading zones. These locations are prone to early surface failure due to vehicle turning, braking, and acceleration.

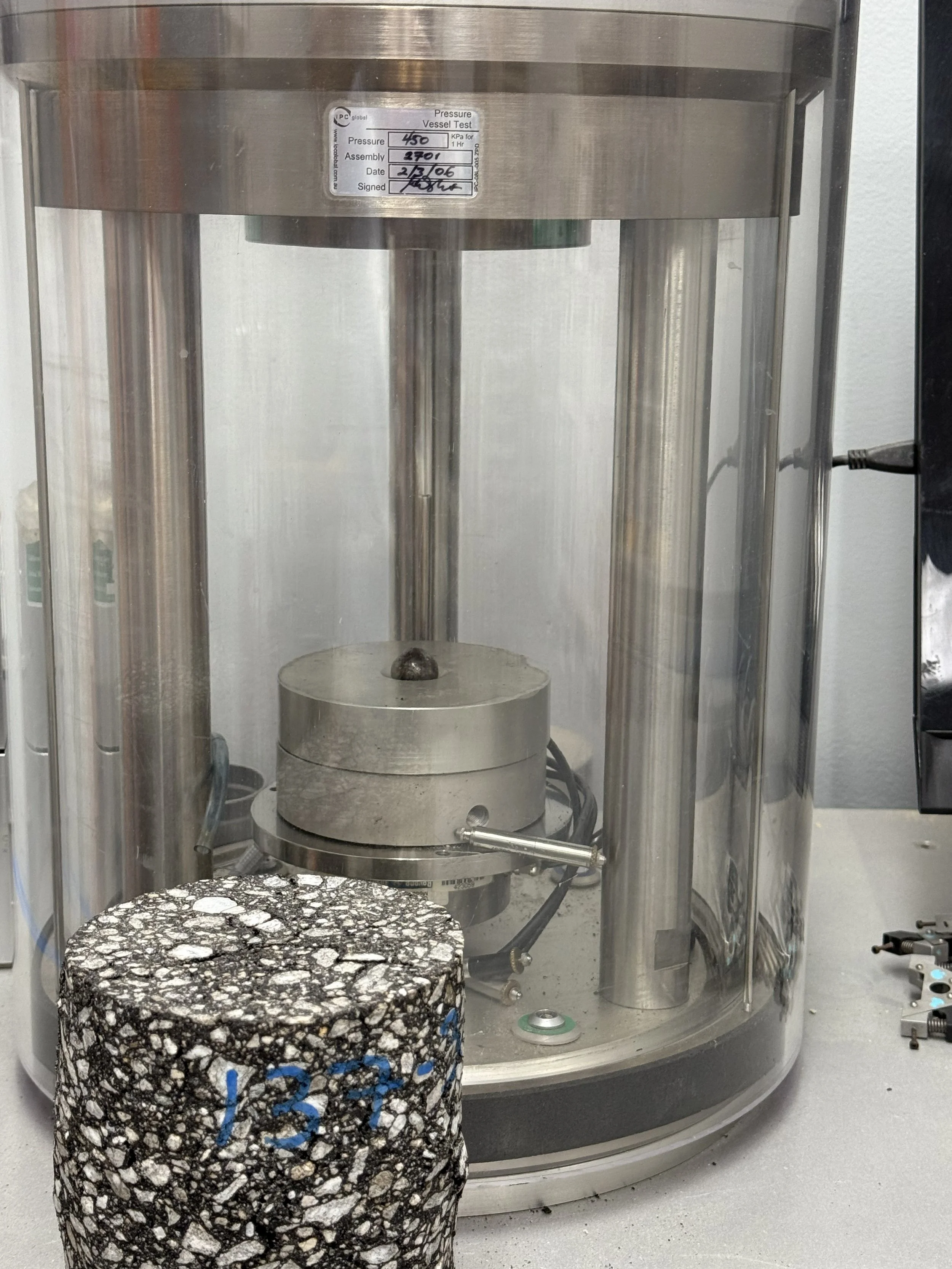

BATT is proud to offer the only asphalt scuff testing service in the U.S., using a state-of-the-art device designed to simulate real-world twisting and lateral tire forces. Our test evaluates a mix’s ability to resist raveling, gouging, tearing, and texture loss—issues that are not detected by standard rutting or cracking tests.

IDEAL‑CT: Fast, Reliable Crack Resistance Testing

IDEAL‑CT (ASTM D8225) helps predict how well your asphalt mix will resist cracking over time—without the complexity of traditional tests. It delivers quick, repeatable results and plays a key role in Balanced Mix Design, especially for pavements exposed to thermal or reflective cracking. BATT uses IDEAL‑CT to help you design mixes that last longer and perform better under real-world conditions.

Hamburg Wheel Test:

Predicts Rutting and Moisture Damage Before It Happens

The Hamburg Wheel Tracking Test (AASHTO T324) simulates years of traffic and moisture stress on an asphalt mix—in just hours. A loaded steel wheel rolls back and forth across a submerged asphalt sample to evaluate how well it resists rutting and stripping, two of the most common causes of early pavement failure.

At BATT, we use the Hamburg test to help you design stronger, longer-lasting pavements that meet performance specs and stand up to the toughest field conditions.

Dynamic Modulus Testing: See How Your Mix Responds to Real-World Stress

Dynamic modulus testing (|E|, AASHTO T342)* measures how stiff or flexible an asphalt mix is under repeated loading at different temperatures and loading speeds. It helps predict how the mix will perform under traffic—from slow-moving trucks to high-speed highway lanes—and under changing seasonal conditions.

This test is essential for understanding how an asphalt mix will behave over the long term, especially in structural pavement design.