Scroll to the bottom to read Tech News

Why a Modern Three-Wheel Polishing Device Matters — And What the BATT Lab Is Enjoying About the Humboldt Unit

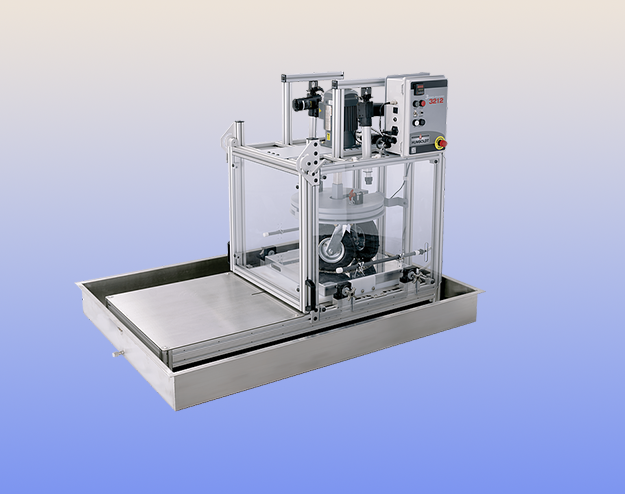

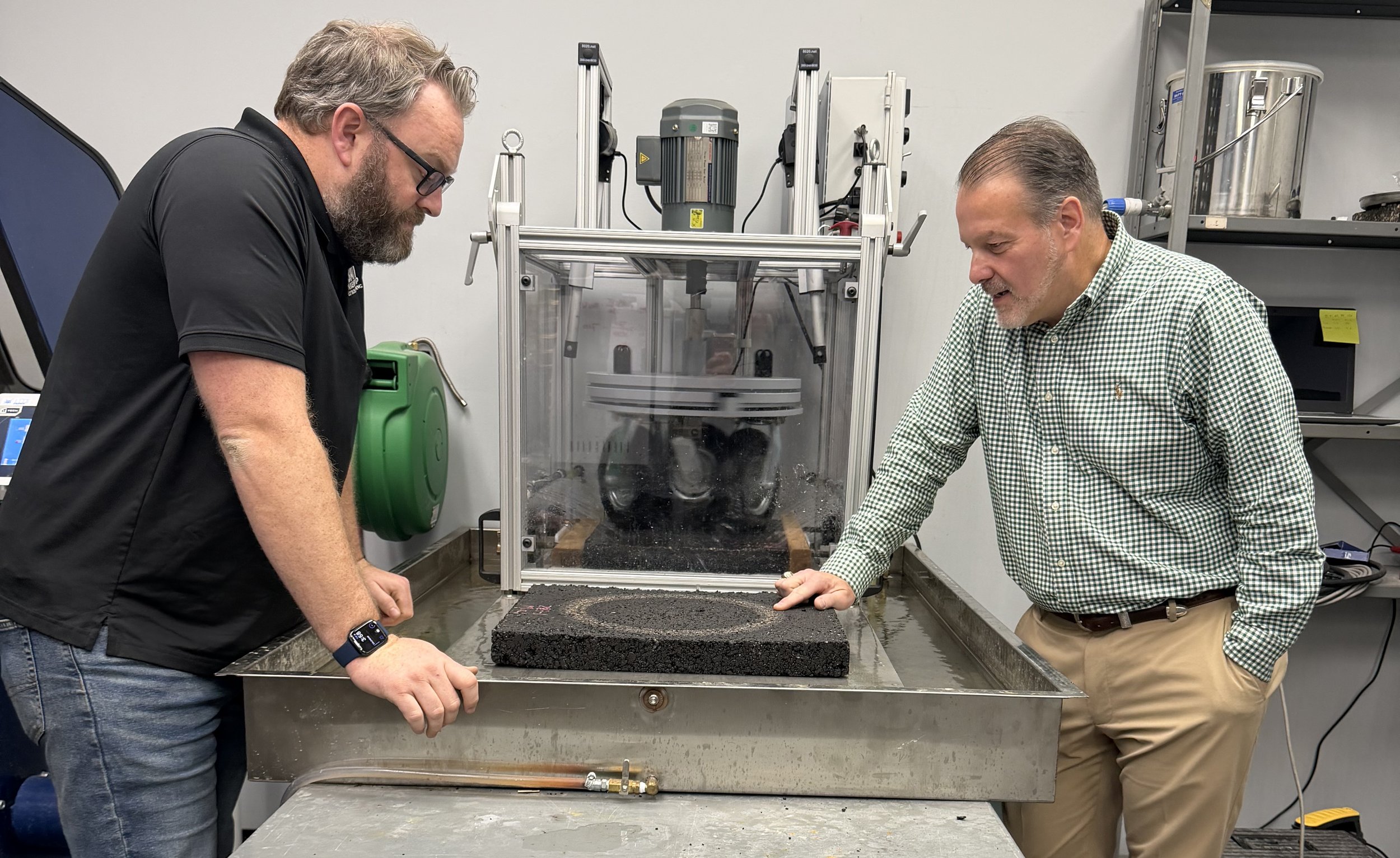

At BATT, we’ve run polishing devices for years, so we started evaluating the Humboldt Three-Wheel Polishing Device. The team has been impressed by several practical features that make day-to-day polishing and follow-up dynamic friction testing more efficient.

What One Million Polishing Cycles Reveal About Long-Term Friction Safety

BATT’s one-million-cycle polishing test is more than a research milestone. If its findings are validated in further studies, they may spark a shift in how friction, polishing, and long-term durability are considered in asphalt mix design.

From Roof Shingles to Road Performance: BATT Supports RenuCore’s™ Lab Validation and MnROAD Pilot Pave

CertainTeed has accomplished with the RenuCore™ technology, an asphalt binder-replacement product launched in 2024 and engineered from post-industrial or post-consumer roofing shingles. CertainTeed called on BATT for laboratory mix evaluation, performance testing, and on-site quality control during a pilot pave at MnROAD, Minnesota’s nationally recognized pavement research facility.

A first in Canada!Alberta Transportation tests an aramid-reinforced asphalt mix to address reflective cracking on Edmonton’s Hwy. 16

In early June 2024, the Alberta Transportation Agency made asphalt pavement history by placing a first-of-its-kind reflective crack relief asphalt interlayer (RCRI) between the road base and the surface layer of the pavement on a section of Trans-Canadian Highway 16.

BATT Supports World’s First Trial of Low-Carbon Asphalt Binder Replacement

The 2025 paving trial using a breakthrough Inverse Vulcanized polymer binder from Uberbinder represents an important step closer toward the transition to low-carbon pavement materials that can be produced and placed with little to no heat.

Train Smarter, Pave Better: How to choose Asphalt Training that delivers the results you need

From Asphalt 101 to highly customized training, BATT offers flexible, targeted training for all levels of asphalt employee teams. Unlike one-size-fits-all programs, BATT focuses on teaching team members how to apply what they learn — practical instruction that equips teams with the skills to perform better, work smarter, and deliver results that stick in terms of better performing pavements.

Testing Innovation on America’s Oldest Highway: BATT’s Ultra Flexible Interlayer Debuts on the PA Turnpike

The Pennsylvania Turnpike Commission hopes to achieve five or more years of service life from this innovative overlay. Opting for a less disruptive and more cost-effective path, the PTC chose to test the innovative RCRAI mix developed by Phil Blankenship, P.E., using a high-asphalt binder content, low-air-void design and Surface Tech’s ACE XP™ aramid fiber reinforcement system.

Expanding Possibilities: How BATT Lab’s new capabilities are powering Better Asphalt Today and Tomorrow

Our newly expanded lab brings increased testing capacity, advanced equipment, and even shorter turnaround times. Curious what a ductilometer is and why it matters? Or how pink paint made its way into our binder lab? Get the full story in our blog!

Ultra Flexibility — the latest advancement in asphalt interlayers

A well-designed flexible interlayer helps distribute loads more evenly, preventing reflective cracking from underlying layers. This adaptability to shearing enhances the pavement’s durability and improves its performance under varying traffic and environmental conditions.

Lab-to-pavement methodology integrates field services with lab testing to achieve Superior Asphalt Performance

BATT’s lab-to-pavement concept seamlessly integrates lab-based mix design, on-site quality assurance and testing, and annual pavement condition inspections to ensure that every phase of asphalt — from initial design to long-term performance monitoring — is optimized to deliver pavements that not only meet rigorous standards but also perform reliably over time.

Why friction testing for asphalt mixes matters — and how to ensure a reliable outcome

Friction testing evaluates an asphalt pavement’s ability to provide adequate tire grip and reduce the risk of skidding or hydroplaning.

Rethinking Asphalt: The Quest for Sustainability in Roadway Construction

Sustainability in the asphalt industry revolves around reducing carbon emissions and extending the lifespan of roadways. We can achieve this by using low-carbon materials, improving durability, and incorporating renewable additives.

Turning to a lab for help with asphalt mix design? Here are six tips that will help ensure you get the desired results.

Want the best results from your asphalt lab? Here are six great tips for achieving the highest performing asphalt mix design.

BATT’s survey of the Hottest Asphalt Topics of 2023 — and what to expect in 2024

In 2023, the asphalt industry felt the impacts of legislation, new specifications for mix designs and an increased emphasis on Balanced Mix Design. This blog explores what the author sees as the most pressing topics of last year and how each will continue to impact the industry.

What’s the Number One reason to test asphalt binders?

Binder testing in the BATT Lab combines decades of expertise with the latest in testing equipment to provide feedback on how a wide range of binders will perform in the asphalt mix.

Pioneering new asphalt pavements: Our commitment to sustainability

The challenge in improving sustainability for asphalt pavements lies in two primary areas where the goal is to produce less CO2: 1) Materials selection (Cradle to Gate); 2) construction methods (Cradle to Site). Improvements in both areas seek to make pavement life expectancy longer (Cradle to Grave), also referred to as pavement Life Cycle Assessment (LCA).

Airport project proves advanced condition analysis + advanced materials + advanced testing = best practices for asphalt paving

In August 2023, the BATT Team wrapped up a project that combined in-depth pavement condition analysis with a unique blend of advanced materials and advanced quality assurance (QA) testing to create a strategy that could well become the standard-bearer for changing best practices in asphalt pavements.

Our AI-based BATT Vision smart pavement monitoring provides over-the-top accuracy in pavement condition assessments

A new service from BATT employs an AI-enhanced monitoring system to produce an accurate and in-depth analysis of pavement conditions. BATT Vision provides a leap forward in detecting the extent and severity of pavement distresses.

Tech News

Tech News

Sept. 24, 2024

by Phillip Blankenship and Michael J. Simmons

Field Performance of Aramid Fibre Reinforced Pavements

Sept. 12, 2023

How much does density matter?

Why do we want more density in a pavement? Density is the unit weight of a mixture. This article looks at various methods for testing density and provides results that show an increase in pavement density results in a positive effect on the overall pavement performance.

Oct. 19, 2022

Environmental Product Declaration (EPD)

FHWA Superb Guidance Document

This EDP tech brief by FHWA is a superb document that explains and outlines the EDP process.

State Departments of Transportation (DOTs) are continually assessing and choosing materials or technologies to meet their transportation needs. As part of this assessment, DOTs are turning to Environmental Product Declarations (EPDs) to quantify the environmental impacts associated with those products.

Oct. 18, 2022

The Virginia DOT took a creative, Round Robin approach to tensile test data for CT-Index

This clever idea could shed light on how to improve the repeatability and reproducibility of Balance Mixed Design testing. A good read.

Oct. 11, 2022

High-strain Asphalt Interlayers using Aramid Polymer Fibers to Mitigate Reflective Cracking in Asphalt Pavements

by Phillip Blankenship, Michael Simons, Vince Aurillio

This paper details the efficacy of an aramid-reinforced asphalt pavement interlayer in mitigating reflective cracking.

Sept. 26, 2022

by Zack McKay

Lab Friction Testing gets a New Standard

The BATT Lab has DFT capabilities and we’ve invested time and resources to make this testing achieve highly reliable results for our clients. This is a good article explaining why DFT takes friction testing to a new level.

Feb. 6, 2022

by Phillip Blankenship

Fix Your Mix

How can we make our asphalt mixes better?

More specifically, what steps can be taken to improve durability, rut-resistance and crack resistance.